CM-ACM

What is CM-ACM:

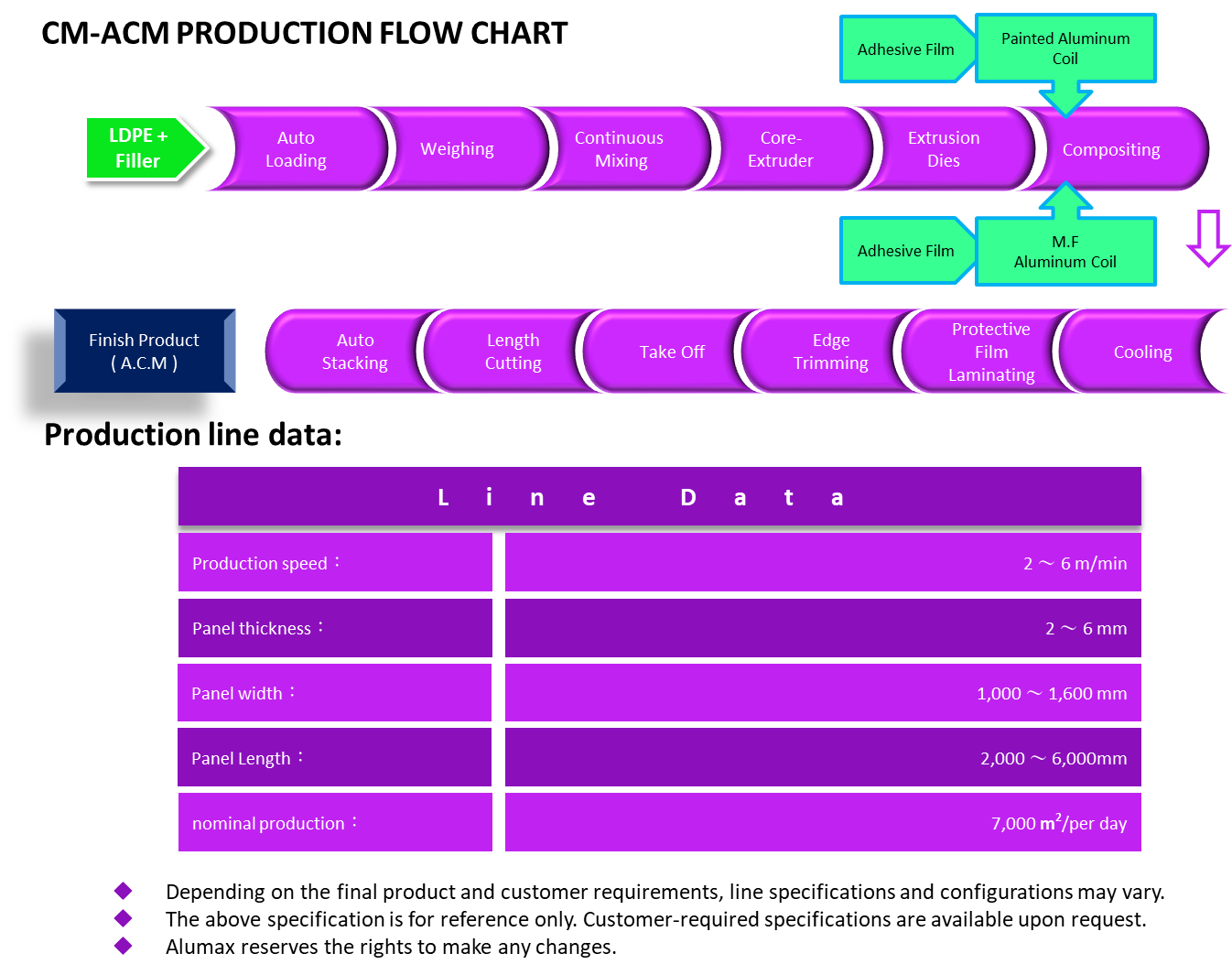

CM-ACM is an aluminum composite panel production line that uses a powerful continuous mixer situated on top of the combined extrusion system rather than a set of internal mixers installed on the floor.

Continuous Mixer:

A continuous mixer is a twin-shaft, counter-rotating mixer designed to continuously mix one or more dry

ingredients, resulting in a uniform mixture of the formulation in a short period of time through uniform mixing and extrusion. To ensure the highest level of throughput and the best mixing quality, the raw ingredients are supplied in constant proportions using a set of loss-in-weight feeders. The raw materials are accurately measured before entering the mixing chamber, and the required mixing volume and intensity are applied. Continuous mixing of LDPE and mineral fillers with the required heating results in a homogeneous mixture that provides extrusion with a consistent and stable mixture of your batch formulation.

Furthermore, an indirect heating or cooling system is used, which is essential for maintaining the right and consistent temperature for the mixture to accomplish the desired mixing qualities. The fully enclosed construction of the mixing chamber has two advantages. First, it keeps the product clean from outside contaminants. Second, it helps reduce unwanted emissions. This, the most advanced method, has recently been used to streamline the preparation and production of ACP.