CES-ACM

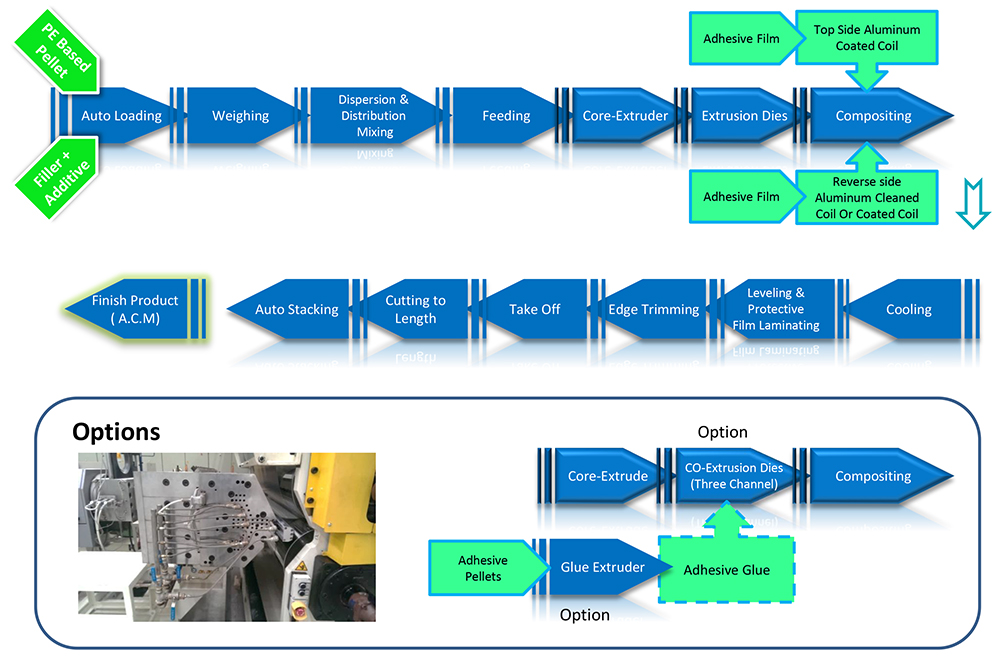

Alumax provides CES is a new system of metal composite panel production line that is the best solution to effectively reduce the cost of core materials. Different from the traditional ACP production line, which uses PE pellets or B1 grade flame-retardant pellets to heat and extrude the core material, and then laminate it with aluminum alloy strip on the upper and lower sides to form a ACP panel ; the CES-ACM production line can directly use recycled PE pellets and mix them with a preset ratio of mineral fillers, it is uniformly mixed , and then the PE core material is extruded and then composite with the aluminum alloy sheets on the both sides to form a composite panel , which can greatly reduce the cost of the core material and can reach more than one million US dollars per year.

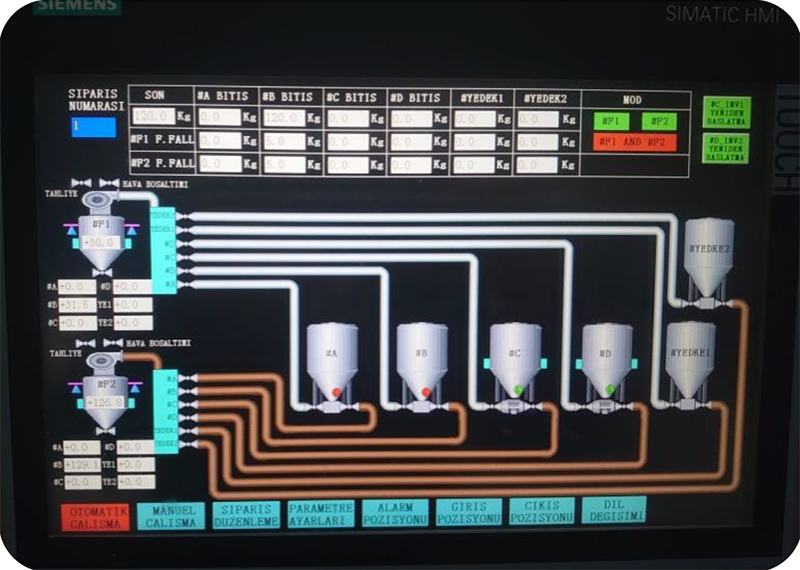

The CES production line directly uses recycled PE pellets from various sources with different models and the quality varies widely . After auto loading and weighing , it is mixed with a preset ratio of mineral fillers, and then mixed by a special mixer and extruder. Extruded into a FR core material, the material costs of the core which compared with the traditional ACP production line using FR pellets can be significantly reduced by 40-60%.

The excess waste core material from the side trimmings of the extrusion core material is recovered. CES Line has zero waste in which the hot softened state is 100 percent reused into the extrusion cycle.

The conventional type of crushing by crusher will cause noise emission & dusting that are not friendly to the environment.

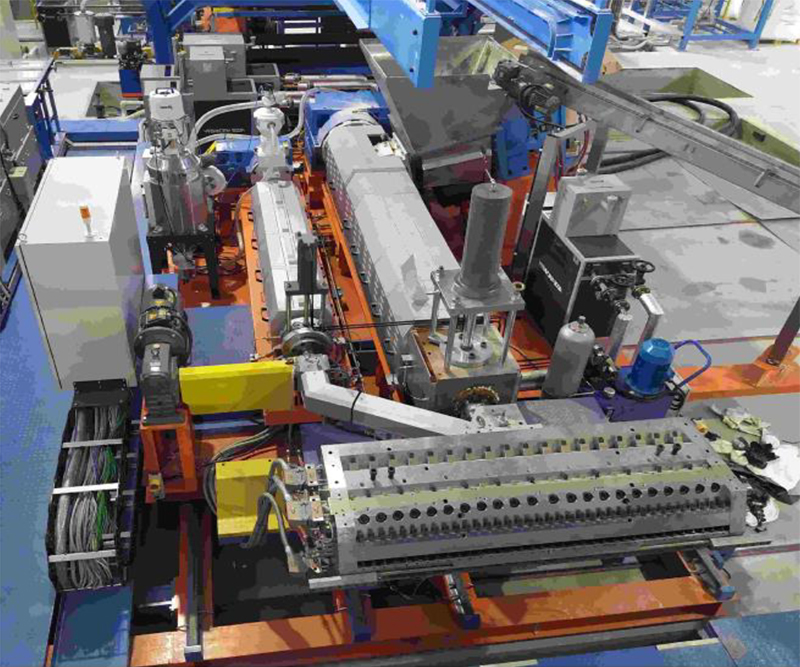

In the CES process, the various proportions of the core material are formed into a hot dough during the pre-mixing process, and then formed into a strip-shaped PE/FR Core material by a pump extruder through an extrusion dies.

Because the pump extruder is shorter than the convention L/D high ratio extruder, the screw is only one-third of it and the required compression ratio and power torque are very low.

The life of the screw is at least 2 years it is easy to disassemble and replace, and the required maintenance cost is low and the replacement time is short. For example when extruded FR cores are used for convention screws, they will wear out in about three to four months, and it takes a higher cost and longer time to replace the new screws.

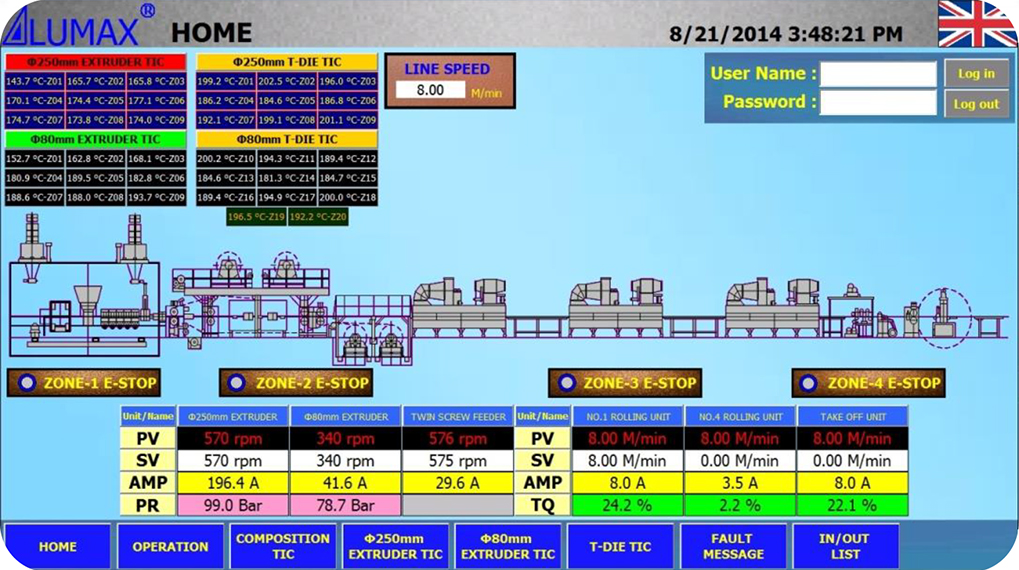

CES is high-capacity ACM production line that produces panels at a high speed of 4 ~ 8 meters per minute.

Compared with the convention ACP production line with the same amount of output, the required energy consumption can be saved by about 30 ~ 40% .

In addition the excess waste core material from the side trimmings of the convention ACP production line is recovered which need to be carefully collected , cooled, and then entered into the crusher. For reuse which to be remix , dry, and reheat are energy intensive.

The relative CES line only needs very little energy consumption and the hot softened state 100 percent is reused in the extrusion cycle.

The CES line most unique benefit is its production capacity. The CES line can achieve a production of the daily output of 7,000 ~ 10,000 square meters of ACM panels it gives a high–level performance, more quality. In addition to the production capacity 2 ~ 3 times greater than a conventional production line, it can also reduce labor costs and energy costs, reduce occupied plant area and plant construction costs performance is excellent.

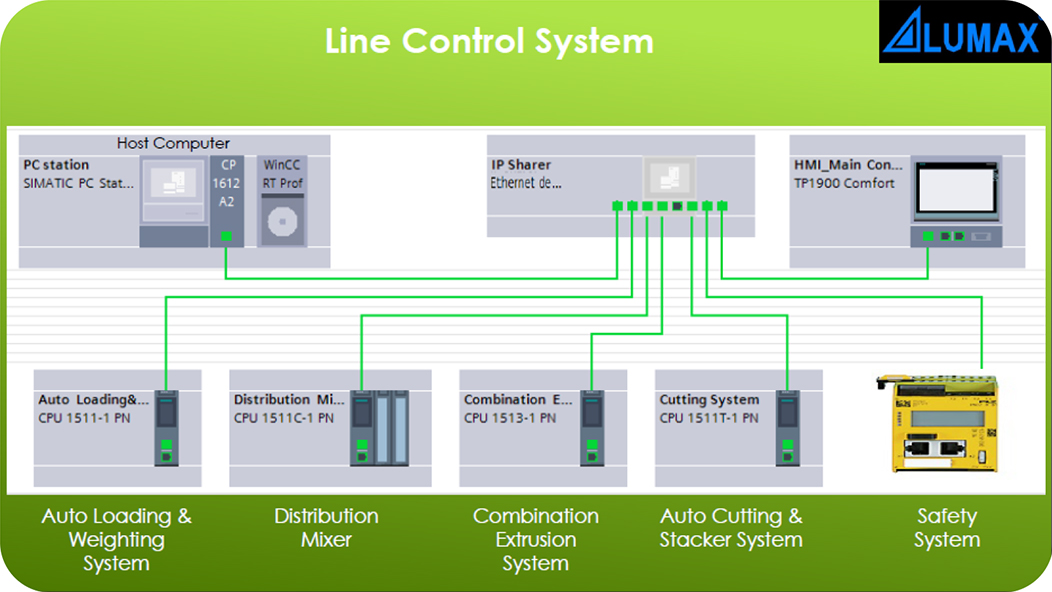

The CES line can be connected and compatible with the latest prime technology industry 4.0 standards.

(With Three Channel Dies)

| Production speed | 2 ~ 6m/min | 2 ~ 8m/min |

| Panel thickness | 2 ~ 6 mm | |

| Panel width | 1,000 ~ 1,600 mm | 1,000 ~ 2,050 mm |

| Panel Length | 2,000 ~ 6,000 mm | 2,500 ~ 8,000 mm |

| nominal production | 7,000 m2/per day | 10,000 m2/per day |

- Depending upon the final products and customer’s requirements, the specification and arrangement of the line may vary.

- The above specification is for reference only. Customers’ specification is available upon requests.

- ALUMAX has the right to make any change.